The instructions on this page are for most common types of Dredges and Sluices.

Setting Up

First you will need to find the place downstream from the area you are going to work, this is so that you will not have to work through your own tailings. If you are going to float your dredge, at this stage you should somehow tie it off to a branch, rock or the bank as the dredge in calm waters has a way of propelling itself up stream and bumping into you.

You can know assemble all the fittings and hoses to suit the area you are working, not forgetting to cheque the oil in the motor if a 4 stroke and that the motor is securely in place as a drowned motor may signal the end of your day.

Priming the Pump

If you have a self priming pump, you will need to remove the top plug and pour water into the pump casing until it is full. If on the other hand you only have a foot valve flapper, you will need to plunge the valve rapidly until you see water come out of the outlet fitting. It is always advisable to not let the intake hose lay on the river bead as it will draw sand and fine particles up into the pump, this will damage the seals in the pump, if you cannot suspend the foot valve from the bottom you may want to place it in a small bucket, this should eliminating the problem.

Priming the Vacuum Hose

NB: The first and best investment advice we can give you regarding a vacuum hose, is to purchase a transparent vacuum hose with a smooth internal diameter, as this will greatly assist you and save you a lot of time in the unfortunate event of trying to locating a blockage, it also makes priming a lot easier as you can see the water in the hose when priming the system.

If your dredge is fitted with a vacuum jet, you are already set to go as this system is self priming as soon as the jet is placed in the water, (dare we say it) as long as the motor is going.

If on the other hand you have a power jet you can prime it a few ways;

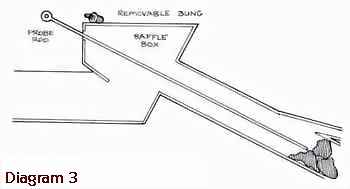

- The easiest way is to hold your hand over the open end of the jet that is fitted in to the rear of the baffle box and force the water back down the hose until water comes out of the normal suction end of the vacuum hose.

- The other way is to submerge the vacuum hose until it is full of water then start the motor just prior to dredging.

|

Operating a Dredge

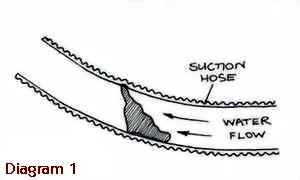

The best method to dredge is to use a prodding motion with the end of the vacuum hose this way it will greatly reduce the blockages and stoppages.

If you are using a power jet, remember not to lift the nozzle out of the water for more than a few seconds or you will have to re-prime the hose. Vacuum jets don't have this problem, so they can be lifted out of the water all day long, the only difference other than design is that the Power jet will give you a stronger water flow, this is due to the design as the Hi-pressure stream of water directly crosses the water at about 10~12° being vacuumed up thus disturbing a greater amount of water.

One

thing you should watch out for while dredging is the gravel level in the sluice. If you notice that the riffles are filling up to the top with gravel you will either more a steeper fall in the sluice or an increased flow of water by increasing the speed of the motor.

Cleaning Up  (This relates to GENERAL Dredges or Sluices) (This relates to GENERAL Dredges or Sluices)

To clean up you will need a container or bucket, it all depends on your methods.

NB: Our Super Sluice systems DO NOT have nor need any matting, carpet or removable riffles, making cleaning up with OUR Sluice system a lot easier and faster. All gold is trapped in our sawtooth riffle system, this is only one specification that makes our system quite unique. (others have unsuccessfully tried to copy our Patented design.)

- Lay the end of the vacuum hose in clean water so that no materials are drawn up the hose, then just let the dredge run.

- Go to the sluice and remove all the large rocks, this will discharge any sand and small gravel trapped around the rocks.

- Slow down the motor to idle speed, place your bucket underneath the end of the sluice, lift up or remove the riffle bars, If you dredging for gold and your dredge has carpet, roll up your carpet and put into a container, then let any remaining gravel wash down into the container then stop the motor. NB: If using Martin Marks Backpack super sluice, at this point, Stop the motor, Pull off the vacuum hose, Remove the trap door, Place the exit end of sluice into your container wash down material with minimum amount of water. (Now, go to step-5)

- Thoroughly wash out the carpet and refit it in the sluice and then relocate the riffles.

- At this stage if you are a two person team, one could go back to dredging while the other carefully concentrates the container.

|

Blockages and Remedies

If you follow the instructions in the operation section above you may never need to stop for a blockage or jam. The most common are half way up the suction hose.

If unfortunately you do get a blockage in your dredge system, one of two things happens;

- You will get a dramatic drop in the suction.

- A reverse flow of water out of the vacuum hose.

|

When either of the above happens, the first thing you need to do is ascertain and locate the type of blockage you have.

Click, the type of blockage.

Blockage in the Vacuum Hose:

This is the most common blockage and it is usually half way up the hose, If you purchased a transparent hose, it will make locating the blockage a lot easier.

You should firstly place the end of the hose so no more material will enter and make it harder to dislodge the blockage.

Once you have stopper the motor, you should be able to simply shake the blockage out, it is usually the force of the water that held the rock in place against the side of the hose.

If you have a vacuum jet fitted, it can also cleared by one of two ways. The first simply involves lifting the nozzle in and out of the water. Alternatively bring the nozzle to the surface so that air and water are drawn into the hose at the same time. Either method will make the water surge quite violently. This method will NOT work with a power jet. This is the most common blockage and it is usually half way up the hose, If you purchased a transparent hose, it will make locating the blockage a lot easier.

You should firstly place the end of the hose so no more material will enter and make it harder to dislodge the blockage.

Once you have stopper the motor, you should be able to simply shake the blockage out, it is usually the force of the water that held the rock in place against the side of the hose.

If you have a vacuum jet fitted, it can also cleared by one of two ways. The first simply involves lifting the nozzle in and out of the water. Alternatively bring the nozzle to the surface so that air and water are drawn into the hose at the same time. Either method will make the water surge quite violently. This method will NOT work with a power jet.

Blockage in a Vacuum Jet: Blockage in a Vacuum Jet:

If you are using this type of jet and the water is still flowing into the sluice but has little suction, it is most likely blockage (A). The remedy to for this blockage is,

you should first tap the front end of the jet on any nearby rock, if this fails, you will need a place the vacuum end of the hose in a position so that no further material can enter the hose causing more material to pack in behind the current blockage, then stop the motor, if you can't dislodge the blockage by tapping the side of the jet with a flat rock, unfortunately you may need to remove the vacuum hose and use a strong branch to force it out, then finally returning the motor back to it's operating speed and away you go.

Blockage in a Power Jet:

With a power jet fitted to the baffle box, you will need to dislodge the rocks with a rod or a tree branch, this depends on your dredge design. If you can't dislodge it this way you may have to remove the jet from the baffle box, to get better access and if unsuccessful the hoses too. With a power jet fitted to the baffle box, you will need to dislodge the rocks with a rod or a tree branch, this depends on your dredge design. If you can't dislodge it this way you may have to remove the jet from the baffle box, to get better access and if unsuccessful the hoses too.

This type of blockage is caused by Over feeding !

|